Large oriented barrier film

High Barrier Oriented Recyclable materials

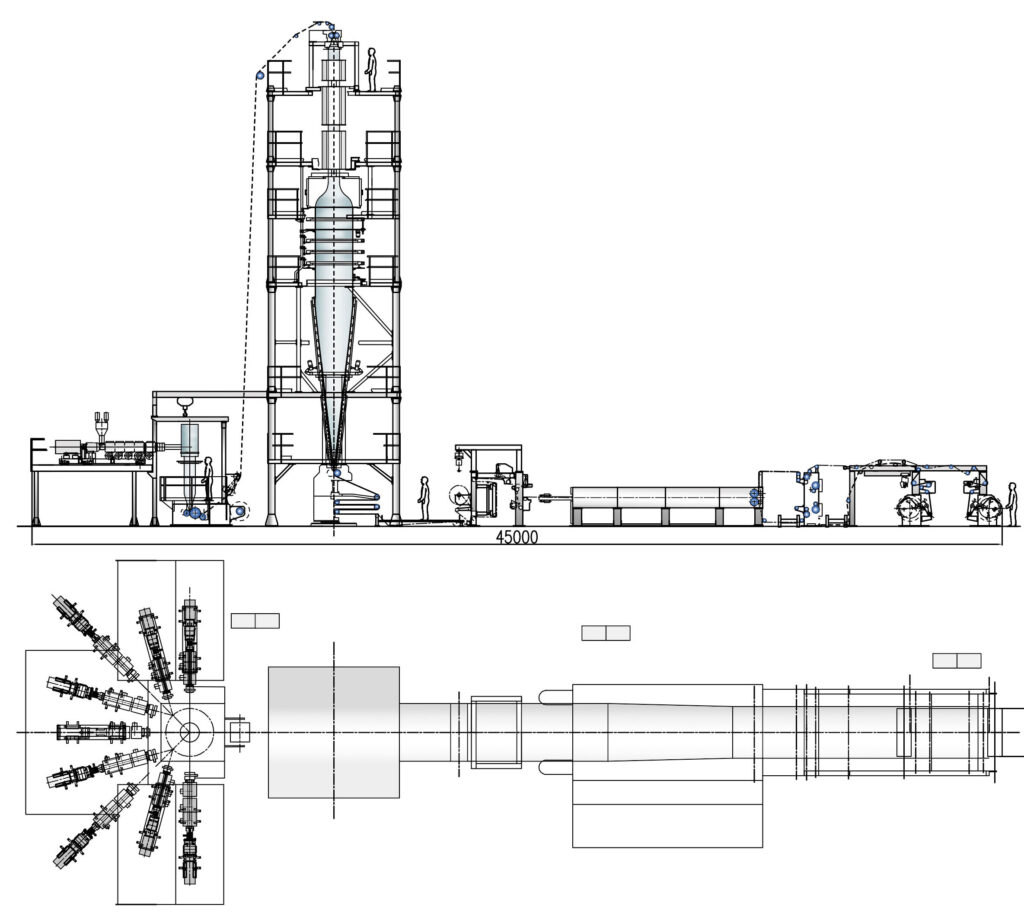

The orientation line works by the so-called “double-bubble process”, i.e. the polymers are extruded through a circular die and immediately water-quenched to form a thick primary tube which is then re-heated up to a suitable temperature and blown to form the main bubble of thin film.

The non-contact simultaneous orientation is achieve thanks to the air inflated during the start up phase. This air allows the transversal orientation while the machine direction orientation is taken simultaneously thanks to the speed different between the stretching nip roll and the tower nip roll.

The bubble is cooled by air and then flattened. The film pass though an annealing ovens to reduce the retraction of the film.

Micro-layers heat shinkable film up to 27 layer

Film with a large number of layers having uniform bi-axial orientation achieved in one step.Having a larger number of and/or thinner layers than prior annular structures improve: barrier, layer uniformity, strength, toughness, tear resistance puncture resistance.

Extrusion Double Bubble Orientation Line Fil Blown Layers

Multilayer barrier and recyclable film . Good replacement of barrier laminated or metalizzed product.

Top lid film with reduced shrink characteristic on both direction which provide to the tray a “drum effect” ideal to pack fresh meat and products with tray and MAP.

Special simultaneous oriented barrier film inclusding PP, EVOH, PA PET ect Thin gauge barrier heat set film. Lamination purpose, lidding ect.

Lamination product for Lithium Battery package To be use as lamination material together with Aluminium and CPP.

Lamination product